Human Intelligence +

Computer Intelligence

Chair has achieved iconic status in the portfolios of designers through its unique qualities of serving its funtionality while providing a test ground for new manufacturing process, structures, experiments and aesthetics. Through the embodiment of chair, I explored different manufacturing processes of the 4th industrial revolution, and how data-based automation and generative design can innovate traditional industrial practices.

Harmonized with the interior.

Generative design process utilizes computer algorithm to automatically produce an optimum design that has minimized mass and cost. To serve its purpose of optimization, generative design chairs typically have similar aesthetics to the skeletons. In order to maximize the potential of the collaboration between human and computer, I finalized generative design process by harmonzing with the interior design of the households.

Chair that mimics Natural Selection

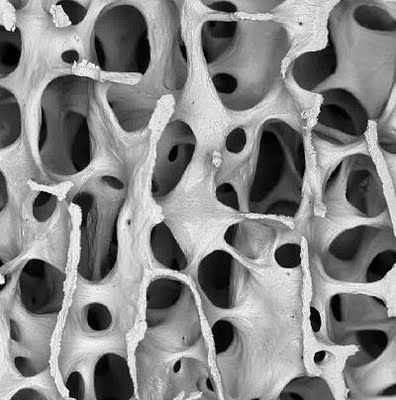

Bone > Frame

Nature has optimized weight and improved stiffness of the bone. Similarly, chair frame will be optimized using computer alogirthm

Nature has optimized weight and improved stiffness of the bone. Similarly, chair frame will be optimized using computer alogirthm

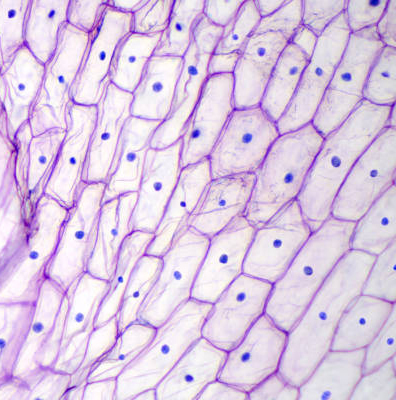

Muscle > Cushion

Muscles have stranded structure to be stiff to hold contraction and to be flexible to stretch. This structure is applied to the cushioning.

Muscles have stranded structure to be stiff to hold contraction and to be flexible to stretch. This structure is applied to the cushioning.

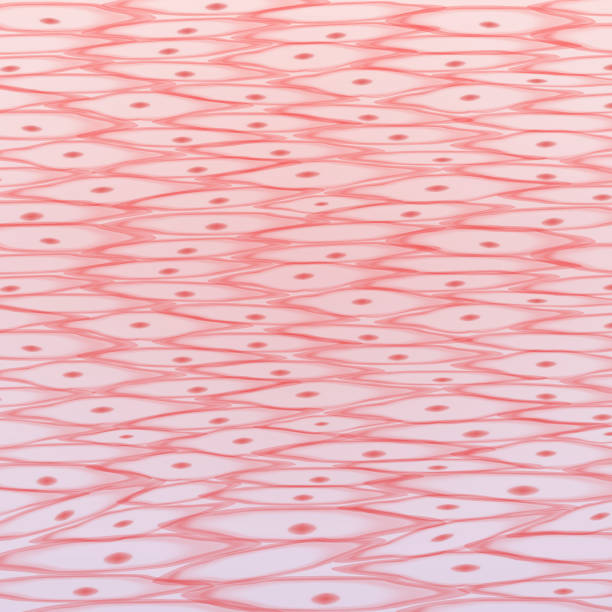

Skin > Upholstery

Skin pigmentation varies among population. This applied in different color variations for the upholstery to match with surroundings.

Skin pigmentation varies among population. This applied in different color variations for the upholstery to match with surroundings.

Bone > Frame

Using generative design, volume and mass of the chair frame has been optimized.

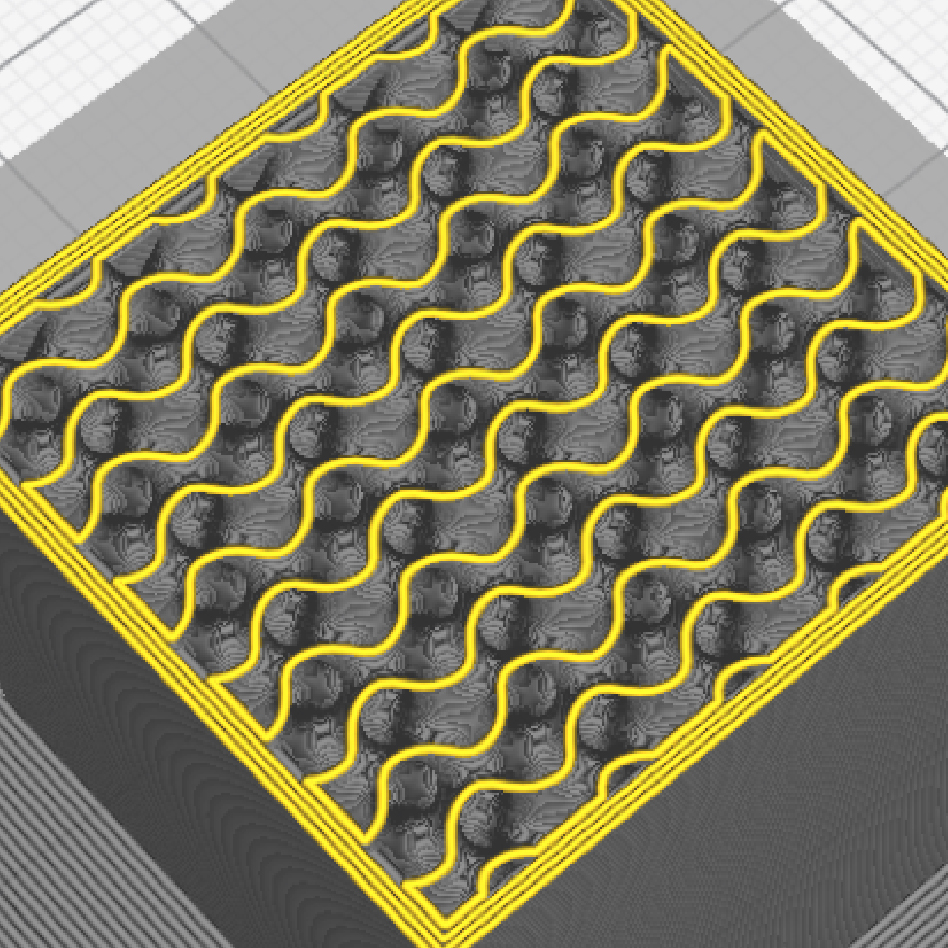

Muscle > Cushion

In order to mimic stranded muscle structure, 3d printer infill was used. By using Gyroid structure of the infill, it will provide comfortable padding while being flexible enough to carry human body weight. Additionally, flexible TPU filament was used to make the cushion robust but squishy.